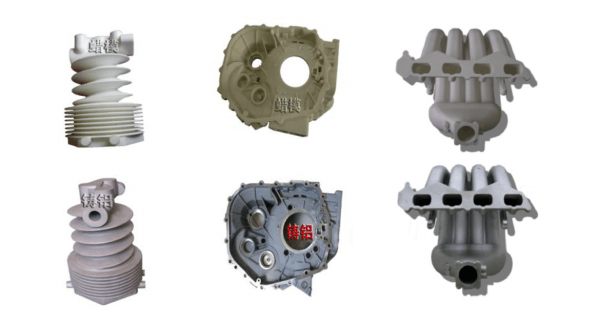

Casting (Master Pattern)

Combine conventional casting method with digital workflow to cope with the fast changing competitive market

Master Pattern

How Sla 3d Printer For Footware Casting

How SLA 3D Printer (KINGS 3035 Pro) Solutions able to help in shorten the process of Footwear Casting Application.

3D System Lost Wax 3D Printer for Jewelry

The ProJet MJP 2500W and ProJet MJP 3600W 3D printers by 3D Systems print in 100% real wax materials to deliver consistent, high resolution patterns for metal casting precision, accuracy and efficiency.

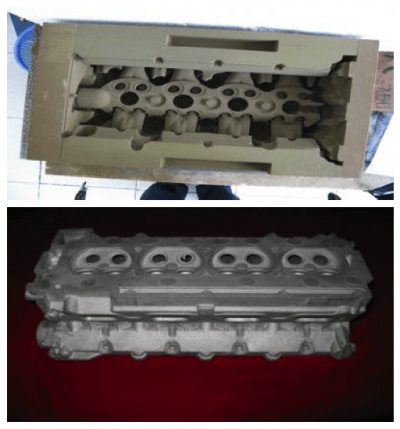

Cast Car Engine Block

Sand Casting part by Shining 3D Industrial 3D Printer – EP-C5050 & EP-C7250

Mould : All the cores and external molds are casted with SLS printed part

Actual Metal Material : HT250

Size : 415 x 260 x 367 mm

Total Process Time : 2 pcs @ 21 days

Application : Simulation test and test run

Cast Car Engine Block

Sand Casting part by Shining 3D Industrial 3D Printer – EP-C5050 & EP-C7250

Mould : All the cores and external molds are casted with SLS printed part

Actual Metal Material : AC4B, T6

Size : 390 x 245 x 176 mm

Total Process Time : 1st Pc @ 10 days, 2 pieces @ 15 days, 6 pieces @ 25 days

Application : Simulation test and test run

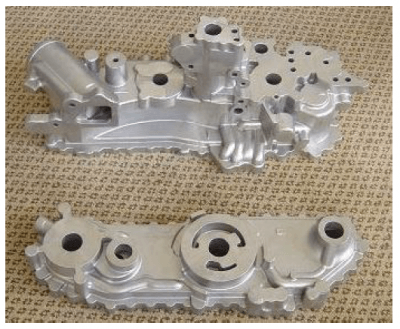

Cast Helicopter Cylinder Cover

Sand Casting part by Shining 3D Industrial 3D Printer – EP-C5050 & EP-C7250

Mould : All the cores casted with SLS printed part. External mold is sand milled

Actual Metal Material : Zl114, T6, First Class Casting

Size : 536 x 245 x 276 mm

Total Process Time : 13 pcs, 15-25 days to complete

Application : Chill is added topically, casted with gravity