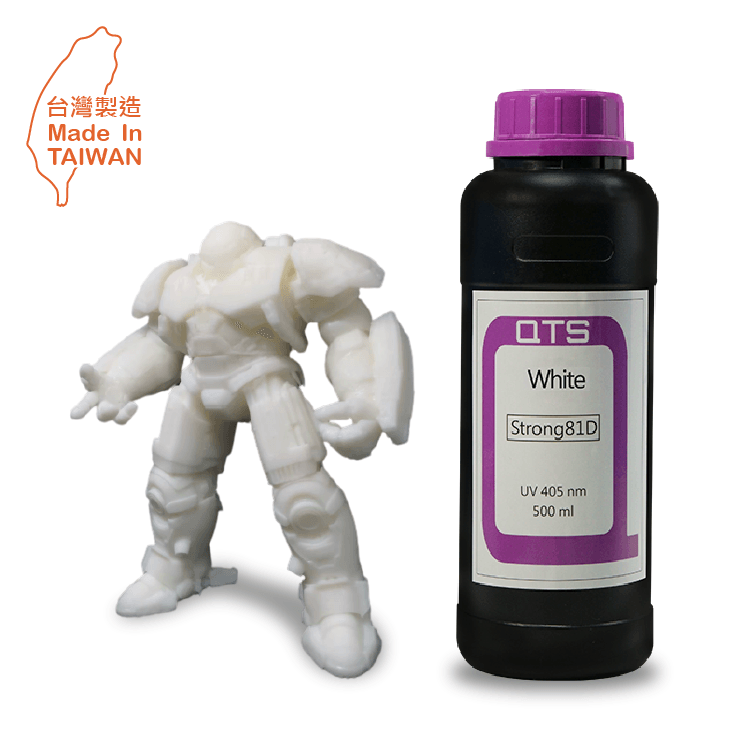

Strong 81D Model

Dedicated For : Zortrax Inkspire, Uniz Ibee, Slash 2, Slash 2 Pro, Uniz Ubee

Weight : 0.5L

Resin Wavelength : 405nm

QTS Strong 81D creates high precision

QTS Strong 81D creates high precision, tough, and low shrinkage parts to be suitable for various applications. It has low viscosity and could be printed with different combination of parameters to minimize production time. The designed mechanical properties can be achieved after curing process.

APPLICATION

- Fasteners

- Hand tools product development

- Automobile interior parts

- Cycling accessories

- Props, miniature, and prototyping

POST PROCESSING

This printed part requires post curing to achieve its ideal hardness and toughness.

- Expose the printed parts in 365 ~ 405 nm UV for 10 minutes to an hour. The time varies based on the thickness of the parts.

- After curing, the color of the parts would dim. Leaving the parts in 70 °C oven for another hour to finish the curing. The process is completed when the color is restored.