3DXSTAT™ ESD-Safe PPS

Dedicated For : Zortrax Endureal, CreatBot F160, Creatbot F430, CreatBot PEEK 300, CreatBot D600 Pro

Weight : 500gm/ 1kg

Filament Diameter : 1.75 /2.85mm

3DXSTAT™ ESD-Safe PPS [Polyphenylene Sulfide]

3DXSTAT™ ESD-Safe PPS [Polyphenylene Sulfide] is a high-performance polymer that exhibits exceptional chemical resistance along with ESD surface resistance. Widely known as one of the most chemically resistant thermoplastic materials available, PPS is insoluble in any known solvent under 200°C.

Benefits of 3DXSTAT™ ESD PPS Include:

- Melting temperatures (Tm) of 285°C

- Glass Transition temperature (Tg) of 85°C

- Excellent chemical resistance, insoluble in ANY known solvent under 200°C

- Stable dielectric constant and dissipation factor over a wide range of temps and frequencies.

- Inherently flame resistant and self-extinguishing

- Long-term hydrolytic stability for very low moisture absorption

- Exceptional strength and modulus even at elevated temperatures

- Melting temperatures (Tm) of 285°C

- Glass Transition temperature (Tg) of 85°C

- Excellent chemical resistance, insoluble in ANY known solvent under 200°C

- Stable dielectric constant and dissipation factor over a wide range of temps and frequencies.

- Inherently flame resistant and self-extinguishing

- Long-term hydrolytic stability for very low moisture absorption

- Exceptional strength and modulus even at elevated temperatures

Typical ESD PPS Applications Include:

- Semi-con: HDD Components, Wafer Handling, Jigs, Casings, & Connectors

- Industrial: Conveying, Metering, and Sensing Applications

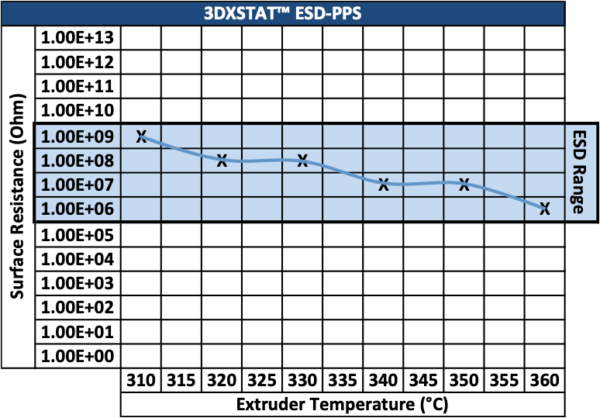

Target Conductivity for 3DXSTAT™ ESD PPS:

10^7 to 10^9 ohm surface resistivity on 3DP sample using concentric ring test method.

Note: Internal studies have indicated that increased extruder temperatures can achieve higher levels of conductivity. Likewise, lower extruder temperatures have resulted in lower levels of conductivity. Each printer is set-up differently as well as varied part geometry. Therefore, expect some trial time to understand how this filament works in your specific printer / application. However, please do not exceed 270°C to reduce the risk of polymer degradation.

Annealing (Post-Crystalizing) 3D Printed PPS Parts:

Parts printed with PPS must be annealed after printing to ramp-up the crystallinity in the resin. This will maximize mechanical, thermal, and chemical resistance properties. Full annealing generally requires 2-4 hours of heating at 130°C. The following process for annealing your ThermaX™ PPS parts will help assure ideal performance.

Place printed parts in cool, room-temp oven. Supports may be left on the part if there is a risk of part warping without them.

Set temp to 80°C and allow to stabilize for 1 hour.

Raise oven temperature to 130°C and allow to stabilize 2-3 hours, longer depending upon the size/thickness of the part.

Turn off oven heat and allow the printed part to cool to room temperature.